Brief introduction of hot-dip galvanized steel types, uses, production technology development process and other issues

In recent years, the hot-dip galvanized steel sheet has been well received by users because of its good corrosion resistance, beautiful appearance, conducive to subsequent processing, reduced costs and reduced environmental pollution. Since the standard electrode potential of zinc is negative than that of iron, the galvanized layer in water and humid air has the function of sacrificial anode to protect the steel base, which can greatly extend the service life of the steel. The galvanized coatings commonly used in industry include hot-dip galvanizing, electro-galvanizing, mechanical galvanizing and thermal spraying (plating) galvanizing, among which hot-dip galvanizing accounts for about 95% of the total amount of galvanizing, and the amount of zinc used in hot-dip galvanizing is It accounts for 40% of zinc production worldwide, and about 30% of zinc production in China. Hot-dip galvanizing is a process technology in which metals such as steel, stainless steel, and cast iron are immersed in molten liquid metal or alloy to obtain a coating. Hot-dip galvanizing is the most widely used steel surface treatment method with the best performance-to-price ratio in the world today. Hot-dip galvanized products play an incalculable and irreplaceable role in reducing corrosion and extending life, energy saving and material saving of steel. At the same time, coated steel is also a high value-added short-term product supported and developed by the state. At present, my country's hot-dip galvanizing industry has entered a new stage of high-speed and sustainable development.

Types and uses of hot-dip galvanized steel

Common hot-dip galvanized steel varieties include galvanized steel sheet and steel strip, galvanized steel wire and steel wire mesh, galvanized steel pipe, galvanized steel and structural parts, galvanized pipe fittings (malleable cast iron pipe fittings), galvanized parts, fasteners, For galvanized device products, common coatings include pure zinc coating, zinc aluminum alloy coating (zinc aluminum rare earth, zinc aluminum magnesium, zinc aluminum lead), zinc nickel alloy coating, aluminum zinc alloy coating (aluminum zinc silicon), etc. Galvanized products are widely used in construction, communications, electricity, transportation, energy, automobiles, light industry (household appliances), agriculture, animal husbandry and fishery, petrochemical and other industries.

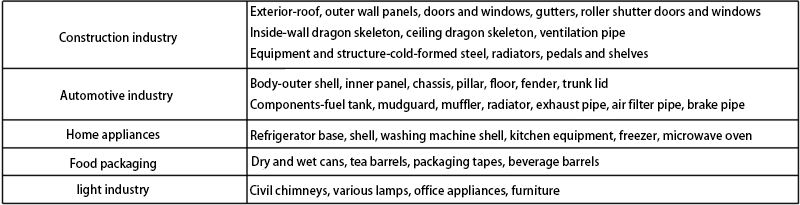

Its main uses are as follows:

(1) Light industry, home appliance industry: air conditioners, televisions, washing machines, refrigerators, microwave ovens, water heaters and other home appliances shells and bottom plates, computer bottom plates and shells, civil chimneys, kitchen utensils, buckets, containers, etc.

(2) Electric power and communication industry: electric power transmission tower, communication tower, cable armor tape, galvanized low carbon steel wire for communication, galvanized steel wire for steel core aluminum stranded wire, hanger, galvanized steel for suspension and fastening Stranded wire. Pole cross arm, pull wire and fasteners, various cable trays.

(3) Construction industry: various industrial and civil buildings use light steel keel, building layer panels, corrugated boards, roof grilles, galvanized pipes for ventilation, water supply and drainage.

(4) Automobile industry: automobile body, door, bottom plate, inner plate, etc.

(5) Transportation industry: highway guardrails, highway isolation nets, road and highway light poles, various indicator signs, and galvanized structural parts for bridges.

(6) Metallurgical and chemical industries: galvanized pipes, structural frames, and various containers for conveying various low-pressure fluids.

(7) Agriculture: sprinkler irrigation pipes, light steel keels for plastic greenhouses, granaries, storage and transportation containers, farm tools, and galvanized iron wires for binding.

(8) Fishery and animal husbandry: steel wire ropes for fishery and net fences for animal husbandry. The development of continuous hot-dip galvanized steel sheets in China began in the 1970s. In 1979, my country WISCO introduced the first modern continuous hot-dip galvanizing production line and color coated steel plate production line from abroad, marking the beginning of modern steel strip galvanizing technology in my country.

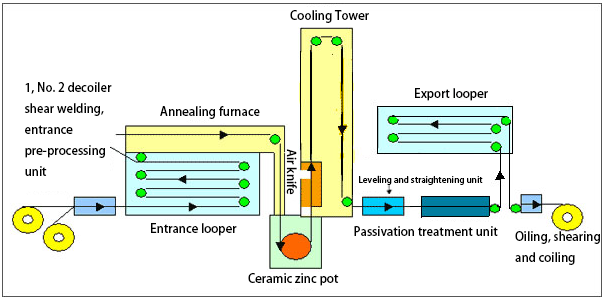

Galvanized steel sheet production flow chart

Due to the strong economic strength and strong technical force of state-owned enterprises, most of the equipment is imported from abroad, the output of units is high, and the product positioning is high. The sales market is mainly for automobiles and high-end home appliances. By 2015, it has grown to more than 70. After 2000, the rise of private enterprises was mainly based on steel distributors. They were familiar with the market and managed well. The hot-dip galvanizing unit equipment used was completely localized, with low unit output, low investment, low production cost, and profitability. High, mainly for low-grade building materials market. By 2008, the production capacity of hot-dip galvanizing of steel plates in my country had reached the level of developed countries in Europe and America. According to investigations by relevant departments, my country's galvanized steel sheet production lines are mainly concentrated in the Yangtze River Delta, the Pearl River Delta, and the Bohai Rim Economic Zone and other developed regions in China. However, under the influence of relevant national policies and market conditions, on the one hand, the original production lines will be concentrated and integrated to a certain extent. On the other hand, the focus of the new production lines will gradually shift to the central and western regions. With the development of my country's economy, industries such as construction, automobiles, and home appliances have developed rapidly and have become the pillar industries of the national economy. The large demand for galvanized steel in the construction, automobile, home appliance and other industries has greatly promoted the market development and technological progress of continuous galvanized steel in my country.

Application examples of hot-dip galvanized steel sheet

Hot-dip galvanized sheet and strip are used in construction, home appliances, automobiles, light industry and other industries. Among them, construction, automobiles and home appliances are the main ones. At present, China not only has the world's largest construction market, but also the world's largest manufacturer of automobiles and home appliances. In recent years, although my country's galvanized sheet has been greatly improved in terms of output, product quality, process technology, and equipment level, there are still the following four problems: 1. There are large differences in equipment levels, and there are more low-capacity units; 2. Excess production capacity, weakening downstream demand, insufficient operating rate of galvanized sheet and strip enterprises, and serious waste of high-configuration units; 3. Non-standard production by private enterprises, low coating thickness, resulting in waste of resources. At the same time, there are weak corporate environmental protection awareness and non-standard corporate environmental management; 4. For high-quality automotive panels, functional appliance panels and high-corrosion-resistant architectural coating steel plates, they still rely on imports, and domestic high-end brands are scarce.

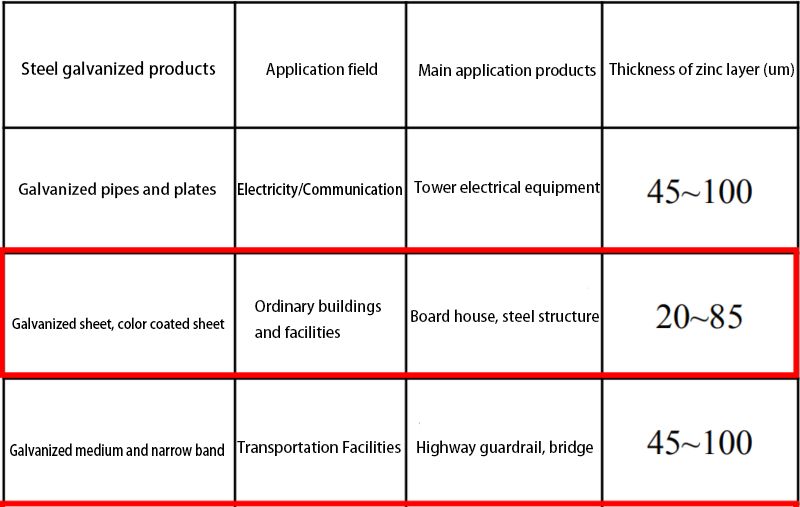

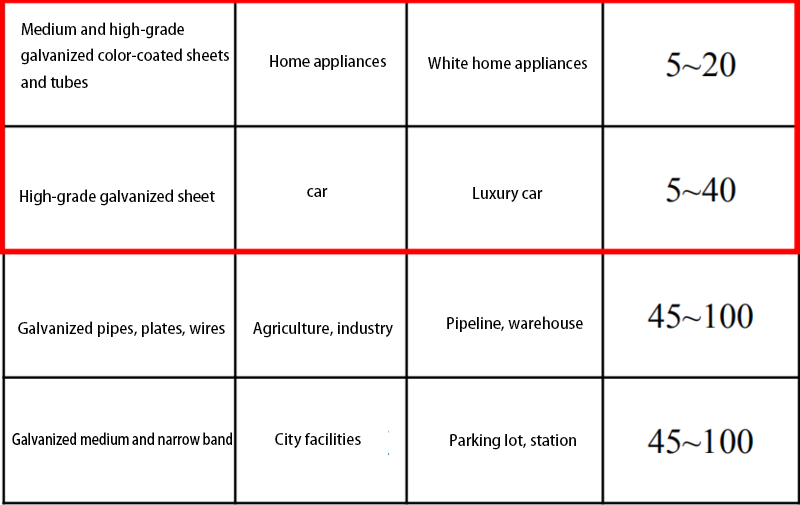

Application areas of galvanized products and galvanizing requirements

Zinc consumption in the iron and steel industry is mainly used as steel galvanized products, including galvanized strips, galvanized steel wire ropes, galvanized welded pipes, and galvanized steel structures. The thickness of the galvanized product and the thickness of the zinc layer will have a greater impact on the zinc consumption per ton of steel, and the zinc consumption per ton of steel of different types and uses of galvanized products vary greatly. With the development of industry standards, the vicious competition of hot-dip galvanized sheets to reduce costs with thin galvanized layers will gradually decrease. Regarding the zinc demand for galvanized products, relevant agencies believe that with the standardization of the galvanizing industry in the future, the total demand for zinc in the steel industry will continue to increase slightly. The consumption of zinc sheets will increase; some mid-to-high-end areas of galvanized steel will gradually replace non-coated steel, and zinc consumption in the galvanized industry will continue to rise slightly.

Main downstream consumer industries of galvanized products

Wagen

Rohbau, Verkleidungsteile, Auspuffrohre, Kraftstofftanks, Behälter etc.

Haushaltsgeräte

Gehäuse für Haushaltsgeräte, Kommunikationsgeräte, Beleuchtung, Verkaufsautomaten, Stahlmöbel, Kleiderschränke, Kleinzubehör, Outdoor-Produkte usw.

die Architektur

Dächer, Wandpaneele, Lagerhallen, Türen, Fenster, Geländer, Wellplatten, Schilder, Bodendecks, Decken, Getreidespeicher, Spülen, Gewächshausrahmen, Container, Wasserkanäle usw.

Elektrizität

Stromübertragungs- und -transformationstürme, Kommunikationstürme, Kabelpanzerbänder und feuerverzinkte kohlenstoffarme Kommunikation

Verzinkter Stahldraht für Stahldraht, Stahlkern-Aluminiumdraht, Aufhänger, verzinkte Stahllitze zum Aufhängen und Befestigen. Masttraverse, Zugseil und Befestigungselemente, diverse Kabelrinnen etc.

Development history of hot-dip galvanized sheet production technology

The development history of hot-dip galvanized steel sheet production technology is as follows:

Units are developing towards high production capacity. The hot-dip galvanizing units built since the 1990s are developing towards high production capacity. There are about 60 hot-dip galvanizing units with a capacity of more than 300,000 t/a in the world, with a total production capacity of more than 28 million t/a. .

Unit specialized production

Automobile galvanized sheets and building materials galvanized sheets are produced by different types of units. The unit technology, single equipment configuration and furnace selection are more reasonable, which makes the investment effect obvious and the product cost is low.

Emphasize the cleanliness of the substrate surface

In recent years, the automobile plate galvanizing unit has basically adopted the American Steel Union process of alkaline solution electrolytic cleaning and full radiant tube heating furnace, and even set up cleaning sections before and after the looper device. In order to reduce investment, building material type galvanizing lines mostly use improved Sendzimir technology, but the line is mostly equipped with a cleaning section to make the surface of the substrate cleaner and the product quality better.

Tower furnace

The investment in tower furnaces is about 25%-30% higher than that of horizontal furnaces. In the past, when the unit production capacity was more than 300,000 t/a, tower furnaces were often used due to the limitation of furnace length. Otherwise, horizontal furnaces were often used. After the 1990s, production plants paid more attention to the advantages of tower furnaces: good furnace air-tightness; fewer furnace rolls and long life; low maintenance costs; help to improve the shape of the plate; shorten the furnace length, etc. Tower furnaces are also used in many galvanizing lines with a production capacity of 250,000 t/a or less. For example, the hot-dip galvanizing unit with a capacity of 250,000 t/a built by the French Solak Steel Company in December 1990; the hot-dip galvanizing unit with a capacity of 250,000 t/a built by the Dudelange Steel Plant in Luxembourg in September 1991; California, the United States BHP galvanized unit and so on. There are also several sets of newly put into production hot-dip galvanizing line in my country using tower furnaces.

Continuously improve the efficiency of the heating furnace

Use the heating exhaust gas to preheat the hot strip to save energy and avoid strip deformation; the continuous furnace is equipped with different cooling sections according to the product performance requirements; the thermal tension adjustment roller is set to optimize the tension of the strip steel; the heating section is set high High-precision anti-heat warping roller, heating section adds induction heater; using drum-pump pulse control burner, multi-stage combustion radiant tube and other heating technologies, improve the adjustment range of the burner and the life of the radiant tube, which is conducive to heating Uniformity, and can reduce NOx content, which is conducive to environmental protection; improve the furnace roll shape design and furnace roll surface spraying technology.

Continuously improve galvanizing equipment

Galvanizing equipment includes air knife, sinking roller, stabilizing roller and auxiliary equipment, zinc pot and galvanizing equipment, etc. Over the years, air knife manufacturers have been committed to improving air knives. The air knives produced by several well-known professional manufacturers such as Fangden, VAI, Duma, and Kohler have their own characteristics. Steel, and maintain a stable distance from the strip steel; enable the air knife to be assembled and adjusted as a whole, and have an accurate positioning mechanism; it can realize the dynamic control of the pressure in the nozzle area; it adopts a double-lip rotary air knife and a better knife lip gap curve, Set up fast knife lip cleaning device; set up the air knife horizontal direction fast and slow opening and accurate reset system, etc., so that the air knife has been greatly improved. The shape, spacing and bearings of the zinc flow groove on the surface of the sunken roll have also been improved, which has improved the stability and life. Zinc pots mostly use ditch-type ceramic zinc pots. The volume of the zinc pot tends to increase to facilitate the stability of the zinc liquid. In modern large-scale units, the lower edge of the sinking roller is usually at least 800mm from the bottom of the pot. The volume should be larger. The development of coreless zinc pot is also relatively mature. SMS has also developed a non-sinking roller zinc pot. According to the principle of magnetic fluid dynamics sealing formed by electromagnetic moving field, a vertical zinc pot is designed, and the strip steel is vertically passed through the zinc liquid in the zinc pot. However, there are no corrosive parts in the zinc pot. This technology has completed the industrial test stage, and has received an order from Eastern Korea Steelmaking, which has attracted the attention of the industry.

Better leveling effect

It adopts a four-roller finishing machine, equipped with dry and wet 2 smoothing processes, large and small diameter work rolls; and the work roll surface adopts shot blasting or electron beam texturing to meet the different extension and surface finish Require. For products of different varieties, good results can be obtained by using different matching methods of the finishing machine and the tension leveler.

Perfect post-treatment process

According to the different needs of users, passivation treatment, phosphating treatment, alloying treatment or organic coating can be used. At present, we are constantly developing and developing better passivating agent formulations. At present, the passivation treatment mainly uses chromate, but activators such as fluoride and phosphoric acid are added to obtain a thicker chromate film; when there is fluoride in the passivation solution, the formation of the passivation film can be accelerated, And make the passivation film fine and bright; in the study of non-toxic or low-toxic inorganic corrosion inhibitors as passivators, a small amount of molybdate and phosphate are added to the non-toxic water-soluble acrylic resin to obtain a passivation Chemical solution (ie ACM) is used to replace toxic chromate for passivation treatment, which can delay the time of white rust on the galvanized layer, and its corrosion resistance is close to the level of chromate passivation, although the technology has not yet Very mature, but out of environmental considerations, chromate-free passivation has become a general trend instead of chromate passivation. The phosphated hot-dip galvanized steel sheet can be used instead of the traditional electro-galvanized steel sheet on the outer panel of home appliances, which can extend the product life and reduce the material cost. The online phosphating treatment of hot-dip galvanizing unit has great potential for development. Anti-fingerprint treatment and the application of inorganic lubricating film and organic lubricating film are research hotspots.

Development of zinc alloy coating

Zinc alloy coated steel sheet has better performance than galvanized steel sheet, so its production ratio is increasing year by year. Among them, aluminum-zinc alloy coating (Galvalume), zinc-aluminum alloy coating (Galfan) and zinc-iron alloy coating (Galvanneal) are developing rapidly. Recently, Nisshin Steel has developed a galvanized aluminum-magnesium alloy coating (ZAM), which has 10 times the corrosion resistance of traditional galvanized sheets. Aluminum-zinc alloy and zinc-aluminum alloy coated steel sheets have better corrosion resistance, paintability, formability, etc. than general hot-dip galvanized sheets, and are suitable for building materials, light industry and other industries. Zinc-iron alloy coated steel sheets have better paintability, corrosion resistance and weldability than zinc-aluminum alloy and aluminum-zinc alloy coated steel sheets, so they are widely used in automobile manufacturing. In order to adapt to the production of zinc alloy coated steel sheets, the galvanizing unit mostly adopts a lifting and moving double plating pot, so that the type of coating can be quickly changed. In 1998, the coreless zinc pot developed by Yingda Company of the United States was put into production. This kind of zinc pot has low energy consumption and low investment, and is very suitable for alloy coating production. Zinc-iron alloy diffusion furnaces tend to use high-frequency induction heating in the heating section, and resistance heating in the soaking section, so as to achieve annealing according to the optimized curve and more accurately control the iron content in the galvanized layer.

Development of zinc-free steel plate

Lead-free galvanizing can produce zinc-free steel plate. This coating can reduce intergranular corrosion, so it has a long service life, is beneficial to environmental protection, is suitable for automobile manufacturing and is suitable for color-coated substrates. A few years ago, Europe stopped producing ordinary spangled steel sheets, so the production of non-spangled steel sheets has a clear development trend.

Develop ultra-deep drawing, high-strength steel galvanized sheet

The production of heavy deep-drawing and ultra-deep-drawing hot-dip galvanized sheets for automobiles are all made of IF steel. The continuous furnace does not have an over-aging section, which simplifies the furnace structure and production control; manufacturers focus on the development of high-strength steel hot-dip galvanized sheets. Generally, high-strength steel contains high Si and Mn content, which is not conducive to the adhesion of the zinc layer. Through the adjustment of chemical composition, especially the addition of Mo, the low-Si content dual-phase steel galvanized sheet and dual-phase steel galvanized alloyed sheet are realized The successful production of steel; the TRIP hot-dip galvanized steel sheet obtained by substituting Al for Si is equivalent to the traditional CM nSi type TRIP steel, but the addition of Al element brings some problems to the steelmaking and hot rolling processes, and this problem is being solved.

Production of ultra-thin coated boards

In recent years, air knives and other equipment have been continuously improved and can produce double-sided hot-dip galvanized sheets with a coating layer of 25 ~ 30g/m². This sheet is mostly used in the electrical industry and can replace part of electro-galvanized or part of electro-tinned steel.

Single-sided hot-dip galvanized sheet is decreasing day by day

The single-sided hot-dip galvanizing process is cumbersome and the production cost is high, so it tends to be replaced by a single-sided electro-galvanized sheet or a double-sided differential-thickness hot-dip galvanized sheet.

Pay attention to the development of hot-rolled hot-dip galvanized sheet

With people's attention to energy-saving and economical materials and the development of thin slab continuous casting and rolling production, more thin-gauge hot-rolled strips can be produced, and the production of hot-rolled hot-dip galvanized sheets has received attention and development, and its products are mainly used in In the field of construction, as steel structure parts, cable racks, ventilation ducts, granaries, etc. At present, the world's hot-rolled hot-dip galvanized sheet accounts for about 8% to 9% of the total output of galvanized sheet. my country's Handan Iron and Steel, Tangshan Iron and Steel and other enterprises have built hot-rolled hot-dip galvanized units.

The level of automation control is getting higher and higher

The whole line adopts computer control, which can realize the speed, tension, centering of the rolling piece, the temperature of each section of the furnace, the atmosphere in the furnace, the optimization of the zinc pot temperature and the closed-loop control of the coating thickness, etc.

Surface appearance defects of hot-dip galvanized steel sheet

Considering the production process of the hot-dip galvanized steel sheet and the packaging of the finished product, the hot-dip galvanized steel sheet may have some of the following surface appearance defects:

(1) Defects of the original board The surface defects of the galvanized original board, such as creases, pits, wavy edges, etc., continue to affect the galvanized board and become its surface defects. Therefore, the producer must inspect the original board before production.

(2) Black spots a. The purity of the zinc coating is not enough. Metal impurities form a galvanic cell on the zinc surface. When it is beneficial to hydrogen evolution, it is easy to cause black spots on the surface of the zinc layer. b. When the content of copper, iron, arsenic and other impurities in the galvanized layer is high, these impurities will appear black after passivation treatment. c. Insufficient treatment of dirt on the surface of the original board will form residues, which will prevent some parts of the zinc from being plated, resulting in defects in the galvanized layer and easily falling off, resulting in dark spots. d. Leakage of plating occurs during galvanizing, and it is easy to form black spots during post-processing. e. Residues or small black ash (carbon or carbon compound) contained in the zinc plating bath adhere to the surface of the zinc layer or reside in the zinc layer, and it is firmly bonded to the zinc layer. Dark spots can be seen on the finished galvanized sheet. f. Abrasive dark spots. Caused by rough operation during transportation and stacking.

(3) White rust The surface of the galvanized steel sheet is immersed in moisture or rain. At a certain temperature, the zinc is oxidized to produce white powder. The anti-corrosion ability of the surface with white rust is greatly reduced, which affects its use. (4) Uneven galvanized layer The zinc layer on the surface of the galvanized sheet is uneven, uneven in thickness, and even small particles on the surface. There is excess zinc liquid on the surface of the strip steel coming out of the galvanizing pot. The excess zinc liquid is blown off with an air knife (jet high-pressure gas) to control the thickness of the zinc layer. The gas pressure of the air knife, the distance between the air knife and the strip, and the speed of the strip will directly affect the thickness of the zinc layer. If the air knife supply is unstable or the air knife pressure is insufficient, the galvanized layer will accumulate, that is, zinc scars. (5) There are residues or scum (metallic or non-metallic inclusions) in the slag inclusion galvanizing bath. Sometimes these slag inclusions are included in the galvanized layer. The Shanghai model ship model mechanical model industrial model makes the surface appear small round spots, Even if the original board is not stained with zinc, it is easy to cause iron spots.

(6) Scratches and abrasions, etc. When the galvanized coil passes through the tension straightening machine, foreign matter on the straightening machine may cause surface scratches and abrasions.

(7) Chromic acid fouling In order to improve the corrosion resistance of the galvanized steel sheet, a very thin passivation layer is formed on the surface of the strip steel, which can be completed by chromic acid treatment, that is, chromium treatment. However, if the chromic acid treatment is poor and there is residual liquid, the surface of the galvanized sheet will appear light yellow band or stains, or even black spots.

More details Link: https://www.wanmetal.com/

Reference source: Internet

Disclaimer: The information contained in this article is for reference only, not as a direct decision-making suggestion. If you do not intend to infringe your legal rights, please contact us in time.

Post time: Aug-27-2021